Chemical pumps play an essential function in a variety of industries. They facilitate the safe and reliable transfer mixing and dispensing of chemicals. They are specifically designed to deal with fluids that are not able to be handled by conventional pumps. Chemical pumps can be divided into two groups: centrifugal pumps and positive displacement pumps.

By partnering with reputable chemical pumps producers and suppliers, you will have access to quality chemicals that conform to industry standards. They leverage their experience to develop and create sturdy, reliable efficient chemical pumps. They employ advanced technologies tools, materials, and manufacturing processes to withstand the corrosive and abrasive nature that chemical products bring. It is essential to work with trusted manufacturers who can provide pumps that will perform well and withstand the harshest circumstances.

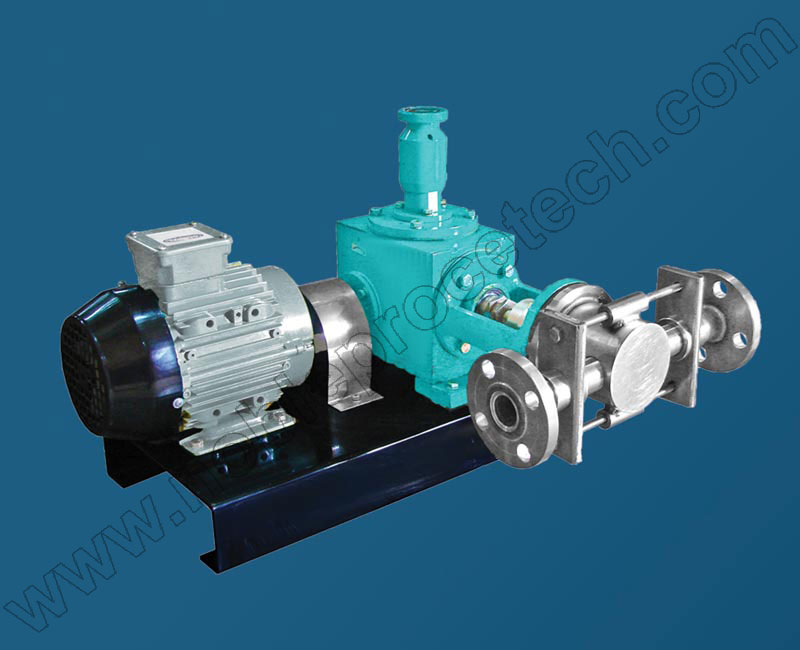

Chemical transfer pumps are manufactured by companies that focus on designing pumps that are specifically designed for fluid-transfer applications. These pumps are capable of handling a wide range of chemicals like acetic, sulphuric and sodium hypochlorite. Chemical transfer pumps are manufactured by companies that focus on efficient control of fluids. These include features such as corrosion resistant materials, leak proof seals, precise flow control mechanisms and more. The pumps are designed to guarantee safe, efficient, and precise chemical transfer operations.

Chemical pump providers have a vital role to play in connecting businesses with the appropriate pumps to meet their needs. They supply a variety of quality chemical pumps from reliable manufacturers. The suppliers provide extensive product catalogs, technical support, and customer service to assist businesses in selecting the right pumps for specific needs. Chemical pump manufacturers ensure that their clients have access to an array of options to select the best pump solution for their needs in the industry.

The significance of chemical pump that are reliable goes far beyond the safety of the fluids. These pumps are essential to keeping the integrity of the industrial process. Unreliability of a pump or malfunctions could cause costly leaks, low performance, and even risks. When chemicals are used like chemical manufacturing or petrochemical industry, the consequences of pump failure can be severe. For more information, click chemical transfer pump manufacturer

Companies can minimize the risk of handling fluids through the use of reliable chemicals pumps. These pumps are built to withstand the corrosive properties of chemical. They therefore function efficiently and continuously for a long time. They are constructed with solid materials, sophisticated seal mechanisms, and precise flow control. These characteristics contribute to a secure and reliable flow of fluid.

Additionally, many chemical pumps are accompanied by comprehensive support and maintenance. The suppliers and manufacturers recognize the significance of these pumps, and so they offer technical support in the form of spare parts, as well as regular maintenance checks. This proactive approach permits the identification and resolution of any potential problems prior to them becoming serious. This ensures long-term pump reliability, and minimizes unexpected downtime.

Chemical pumps are utilized in a variety of industries, such as chemical manufacturing, food processing and Petrochemicals. These pumps are vital for mixing, fluid transfer and dispensing within these industries. Chemical pumps can also be utilized in high-temperature heating systems as well as off-site applications in refineries. They are essential to industrial processes due to their versatility and capacity to deal with challenging liquids.

It is essential to think about factors such as the type of fluid that is used along with the flow requirements, operating conditions, and compatibility. A reputable chemical pump manufacturer and suppliers can provide guidance and support when selecting the best pump for particular requirements. The importance of safety, efficiency, and reliability is essential when selecting a chemical pumps to stay clear of potential hazards maximize productivity and reduce downtime.

Chemical pumps are utilized in refineries for a variety of reasons. They’re versatile and play an important role in the transfer of chemicals off site. Chemical pumps are crucial for the smooth operation of refineries, whether they are used to move corrosive fluids into storage they can aid in loading and unloading of tanker trucks, support maintenance and repair and ensure that chemicals that are corrosive can be transported. They are crucial for applications that require accuracy, safety and effectiveness when dealing with corrosive and chemicals that are abrasive. When investing in high-quality chemical pumps, and collaborating with reputable manufacturers and suppliers refineries can build a strong foundation for their off-site operations, and ensure flawless and efficient chemical transfer across a range of environments.